Why Hand Block-Printing Costs More Than You Think (and Why That’s a Good Thing)

At The Yard House we love sharing stories behind our collections — and none is more worth telling than the making of a true artisan block-print. When you pick up a piece with hand-block print, you’re investing in time, skill, material and heritage. Here’s why block-printing by hand is so *tedious*, so *meticulous*, and yes — more expensive than machine-print.

1. Space and Real-Estate Intensive

Block printing doesn’t happen in compact workshops — it needs space, air, and movement. The “real estate” of the printing table is one of the biggest invisible costs in the process.

Each length of fabric is stretched and pinned onto long, padded wooden tables that typically run 12 to 25 metres in length and up to 5 feet in width. These tables are arranged in large, open halls with high ceilings to allow good ventilation and even drying.

The printer works at one end of the table, stamping colour by colour, and then walks the entire length of the fabric — repeating this process over and over for every colour layer. Once the full length is printed, the fabric must stay laid out until the colour dries completely, which can take several hours or even overnight, depending on weather and humidity.

That means each table can only accommodate one batch at a time — and with limited tables and long drying times, throughput is naturally slow. Maintaining such large printing spaces is a significant cost.

2. The Hidden Cost of Block Making

Before a single metre of fabric is printed, there’s an entire art behind making the blocks themselves.

Each block is carved by hand from seasoned teak or sheesham wood — chosen for its ability to hold fine detail and withstand repeated stamping. The artisan meticulously draws and then carves the design, keeping in mind how it will repeat seamlessly across metres of fabric.

Once carved, the blocks are soaked in oil for several days to prevent the wood from cracking and to prepare it for long-term use. But even then, each block has a limited life — with every press, its edges wear down slightly. After printing a few thousand metres, the block loses precision, and new ones have to be made.

Creating a full set of blocks for one design can cost anywhere between ₹5,000 and ₹75,000, depending on the number of colours, the intricacy of the motif, and the size of the repeat.

3. One colour, one block, one pass

- Each colour usually has its own carved wooden block.

- The printer stamps one colour, often from left to right (or one end of table to the other) beneath the fabric running the full width.

- They must wait for this colour to dry or set before the next colour pass begins — otherwise the next colour would smear.

- Depending on the design complexity and number of colours, a single piece might go through 5-6 (or more) “passes”.

All of this means labour time is high, error risk is high, and the entire printing run is constrained by sequential layers. The more colours, the higher the cost.

4. Weather Dependence

Hand block printing depends on open-air or well-ventilated drying, and the timing of each stage is rigid. How many metres can be printed per day, per artisan – contributes to cost.

If the fabric doesn’t dry properly before the next colour is applied, prints will smudge, mis-register or bleed. That means:

- If there’s high humidity, rain or monsoon conditions — the printers cannot move at full speed.

- A table that is fully loaded may have to wait for the preceding layer to set. This cuts down the productive months in a year — for many artisan clusters the “printing window” is restricted by weather.

- The weather-dependence thus reduces throughput.

5. Pre- & post-process: washing, drying, fixing

It’s not just the “printing” part. To ensure durability, colour‐fastness and aesthetic finish:

- The fabric often gets a pre-wash to remove sizing, oil, impurities so that the block print takes properly.

- After printing, the fabric is washed, cured and sun-dried to fix the colour. Without this step, the print may fade, bleed, or not bind properly.

- The drying (often under sunlight) means dependency on weather again, and time is lost when drying conditions are poor.

These “hidden steps” take time and cost — labor, space, time.

Typically fabrics of 48″ or 60″ width are manageable; wider widths are harder to handle, dry and process.

6. Skill, training & precision

Block printing is not simply a manual “stamp and go” job. It requires:

- Highly trained artisans who can align the blocks, ensure repeat consistency, ensure registration (blocks lining up) and monitor colour deposit.

- Experience to judge how much colour to apply, how heavy the block should press, how it will dry, how the next layer will sit.

- The margins of error are tiny; any mis-alignment, any smudge, any improper drying leads to waste.

Because of this, you’ll often see that younger generations of artisans are reluctant to take up the craft unless the pay is good – so the supply of skilled block-printers is constrained.

7. Colour mixing by hand, trial & error

Unlike automated screen-printing where colour mixing and inks can be standardized, many block-printing units:

- Mix dyes (or prepare inks) by hand – achieving the exact tone required.

- Each batch may require “strike-off” (a sample print) to check the tone, deposition, drying behaviour.

- If the tone is off, the whole batch may need adjustment, or in worst case re-print. Each repeat means labour and waste cost.

Hence the cost of “right colour” and “right batch consistency” is built-in.

8. Why you pay more — and why that’s worth it

Given all the above, the cost headers look roughly like:

- Skilled labour time (artisanal rate)

- Blocks carving and maintenance

- Multiple colour passes (each pass adds time)

- Pre-washing and post-washing/drying/fixing

- Space & real estate cost (large table, drying area, wait times)

- Waste/scrap due to manual error

- Colour batch mixing and strike-off testing

- Dependency on weather/drying – leads to lower output & higher per-unit cost

But here’s the upside:

- Each piece carries authentic artisanal value.

- The prints have character, slight variation, human feel — this is unique.

- The material becomes a story — “crafted by hand”, not just “mass-printed”.

9. What you should look for (and what we ensure)

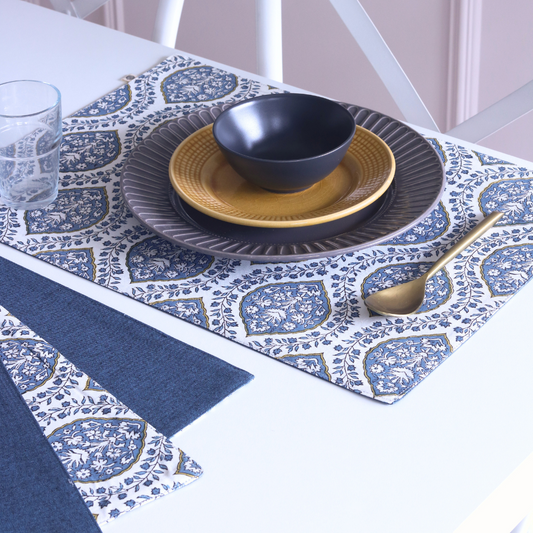

When you see a genuinely hand-block printed piece, you’ll notice subtle variations in prints, slight differences at joins, a rich feel, and excellent finishing.

At The Yard House, in our Hand Block Printed Collection, we ensure:

- Use of good quality fabrics and preparation for the block-print process.

- Skilled artisans who take the time for multi-colour passes.

- Proper washing and drying post-print so the fabric performs well in daily life (wipeable, anti-slip, easy to clean still requires this finishing).

- Colour batches tested for consistency so you get the tone we intend.

Because of all this, our block-printed offerings may cost more than fast-mass prints — and we believe it’s a superior value for your home.

Thank you for choosing pieces that carry the time, care and heritage of hand-block printing. When you pick a block-printed tablecloth or runner, you are directly supporting artisan communities, preserving a craft, and choosing depth over volume. We hope this helps you appreciate the value behind the price.

Hand block-printing is slow, exacting, weather-sensitive, skill-intensive and beautifully imperfect. The cost isn’t just for the fabric or pattern — it’s for the human hours, the drying sun, the careful dye mixing, the artisan’s eye aligning block after block. It’s a craft worth preserving, and a piece worth owning.